You are very kind to respond, and that is a very thorough review of order of operation you must have answered this question before. A printer, router, knife, laser, they all do the same x,y,z motions from a very KISS perspective. Frequently I think of my router like a printer, since I have been using a computer since the mid 80s. Thanks Leo, I may not have the terminology correct, but I do understand the order of operation, I have read the Vectric book for Aspire(s), and recently re-read "getting started" volume as applicable. Those are 5 separate individual operations.

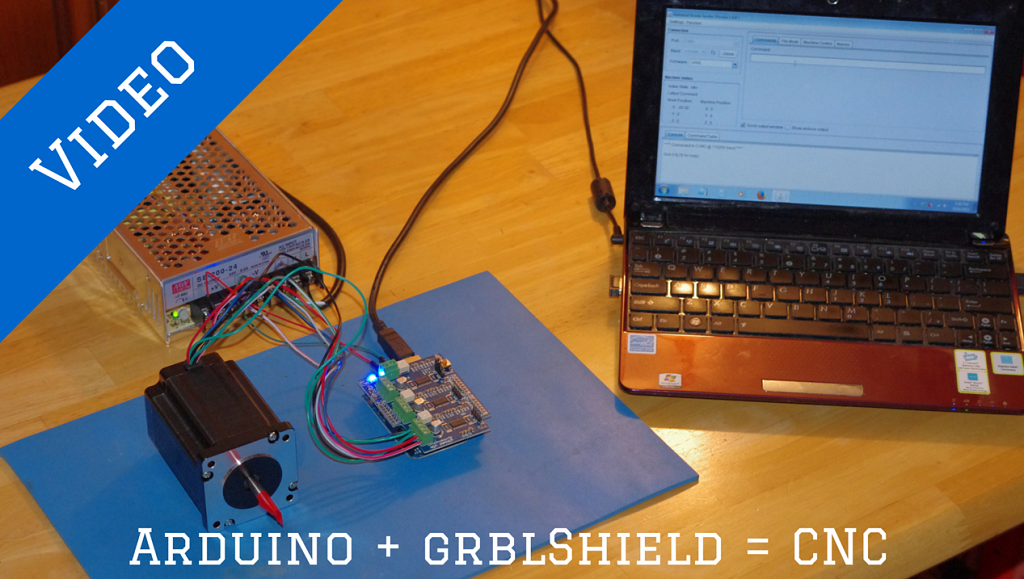

#Cnc usb controller software motor tuning code

So - the order of operations from IDEA to cut out finished part is this:ģ) Post process (convert the graphical CAM into machine control readable code)Ĥ) Load the machine code into the machine controller (computer at machine)ĥ) Setup and cut the part on the machine. It uses the toolpath information from CAM and converts it into the language that the machine control software understands - very often that is G-Code. It is NOT cad, or cam, or a machine control. CAM, uses the graphical design that we made in CAD and creates toolpath on the model (even if only 2D vectors) created in CAD. It IS the beginning of the process to design your creationĬam is NOT CAD, though SOME CAM software has CAD ability build into it - like the good people at Vectric did for us. Aspire, other software/CAM, ArtCam, Autocam, Delcam, or any other CAM - or CAD - it NOT operating softwareĬad is specifically a "drawing" application - it does NOT generate and g-code or any other thing to run a machine. Mach3 is popular but there are others are well.

The control also has software, APP, Application, program - or whatever you want to call it. The control has a printed circuit board that each axis motor is plugged into (hardware). This is generally a computer that the machine plugs into The machine is NOT smart, and has NO brains - it cannot do anything on it's on. The machine has motors on it to move the axis motions, and has a spindle There are a few entities that need to work together. I think it's somewhat common as the hobby world starts to get into CNC that operators don't really understand what is going on. Other criteria, is 4th axis support included or added on? Bob Cad was a $600+ mistake, so this time I'm asking for opinions of a wider community. I purchased Bob Cad for the same reason initially, and then I switched to Aspire. well its a heck of decision with no caffeine this early in the day. But if I switch off of the mfg's cards and software. When you create a tool path with 6 cuts into MDF around letters and it is off 1/8" inch consecutively, and rebooting isn't working, I've got a problem somewhere, and third time of attempting to isolate and creating new tool paths hasn't worked. I do know Artsoft has a Yahoo Group, but I haven't joined yet. I want post processing software with a great user group and support. Is there a digital machining magazine that has reviewed all the post processing software? DWC is using planet CNC USB, now, but from our own facebook user group, the users still have problems with it. I have been reading equipment reviews in husbands woodworking mags almost all my life I think I have most of the fine woodworking magazine, Shop Notes, Woodworkers Journals, so I grew up on reading reviews of equipment. I feel like talking Post processors is entering a brave new world, so here is my question.

0 kommentar(er)

0 kommentar(er)